Idemitsu Australia’s Boggabri Coal Mine was recently forced to close the entire mine while it got on top of a Covid outbreak. The mine was forced to isolate large numbers of staff while New South Wales Health conducted contact tracing. While it was ultimately reported as a false positive it demonstrated the health and safety, legal and operational risks facing mining operations.

The emergence of new more infectious Covid variants is now forcing mining companies of every size to reevaluate digital contact tracing solutions to stay open and meet their Health and Safety obligations. This article describes the lessons RightCrowd has learned in partnering with its Mining customers to keep people safe and mining operations running.

Digital Contact Tracing Changed the Game for Mining

In early 2020 the first smartphone-based digital contact tracing apps were released to fight the spread of the SARS-CoV-2 virus. Across the industry, digital contact tracing has many definitions, including smartphone-based applications, QR code-based systems and a range of wearable devices (badges, cards, wristbands, watches etc).

Over the course of 2020/21, RightCrowd has worked with global resources giants, Wall Street financial services leaders, US Manufacturing giants and Government agencies to implement its unique Bluetooth Low Energy (BLE) wearable contact tracing technologies to record close contacts between people. The resulting list of contacts allows local health authorities, outsourced contact tracers and companies to notify people they have been exposed to a COVID-19 infected person faster.

Digital Contact Tracing Twice as Effective

As part of a proof of concept, RightCrowd worked with a US Pharmaceutical leader to compare the results of manual vs. digital contact tracing. Both companies were surprised to see that digital contact tracing was twice as effective in identifying close contacts than manual contact tracing processes. This result can be attributed to simple human recall errors, where people cannot remember every person they interacted with each day.

With Delta being transmissible through casual contact, the Alpha strain rule book has been thrown out the window. No longer can companies rely on manual contact tracing interviews to protect people and keep critical operations open

Identify and Mitigate Mining COVID-19 Risks

At the time of implementation, New Zealand was COVID free, yet the New Zealand Department of Corrections ordered 6,000 RightCrowd Contact Tracing badgeholders for staff, contractors and visitors to use for contact tracing in its 18 prisons.

General Manager of operational delivery Brigid Kean said cellphones were a contraband item in prisons, which meant its staff, contractors and visitors weren’t able to use the (cellphone-based) Covid Tracer App.

Prior to implementing RightCrowd, New Zealand Corrections had been using paper-based records which were then entered into a spreadsheet, which had been a slow, manual process with significant room for error.

New Zealand Corrections identified COVID-19 outbreaks as a critical operational risk, like many organizations globally, and implemented the solution to get ahead of the curve

Protect Safety to Protect Mining Operations

The manufacturing industry globally has seen high uptake of digital contract tracing solutions. Often highly skilled labor work in close proximity for long periods with obvious safety risks. Manufacturers also identified that the impact of a production shutdown can run into the millions of dollars daily.

RightCrowd is working with a number of major global manufacturers, who identified their COVID-19 risks very early in the pandemic and sought solutions to mitigate their critical safety, operational, contractual, and reputational risks.

A leading client found that if it protected its people first, through an appropriate set of COVID-19 safety measures that included digital contact tracing, it could better mitigate its COVID risks at a lower cost.

Data-Driven COVID Response

David Coe, Health, Safety, Environment and Community Manager at Stawell Gold Mines said Safety is our number one priority and it’s incredibly important that if we have an active Covid case onsite we keep our people and community safe. The data from the system has been really valuable, its identified that most people come in contact with about 25 people per day. So instead of removing 130 people from site, we can accurately identify close contacts and manage them. We understand our risks better’.

The major impact is that exposed people are identified rapidly and their health can be looked after as a priority. Previously the Company would have been forced to remove whole teams, with huge impacts across operations. Mr Coe noted that HSE is part of our operating model, and RightCrowd Contact Tracing helps us keep our people safe and our operations running’.

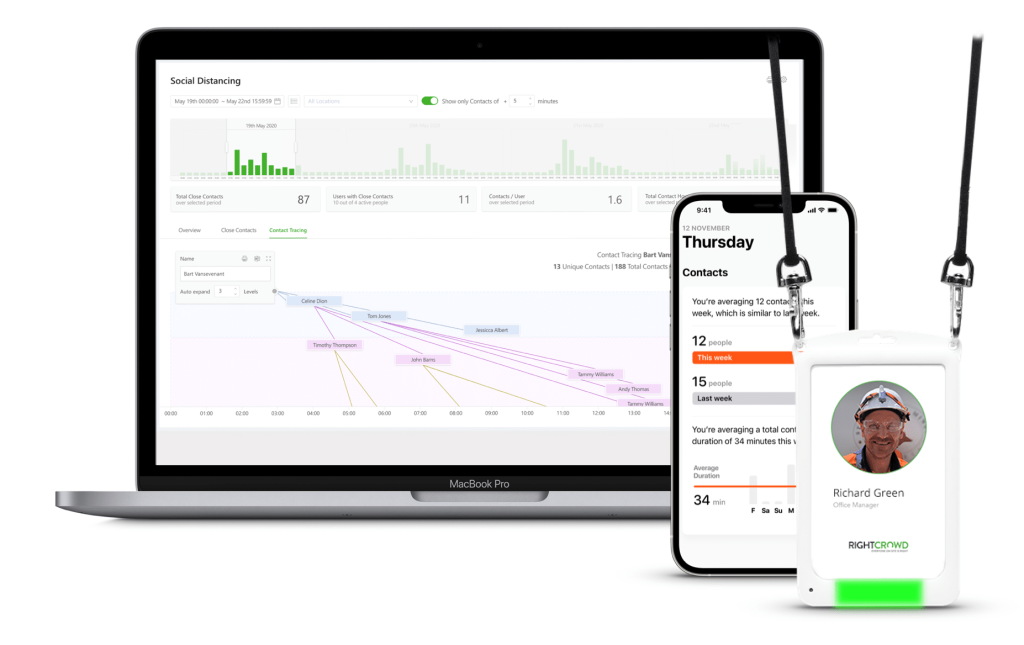

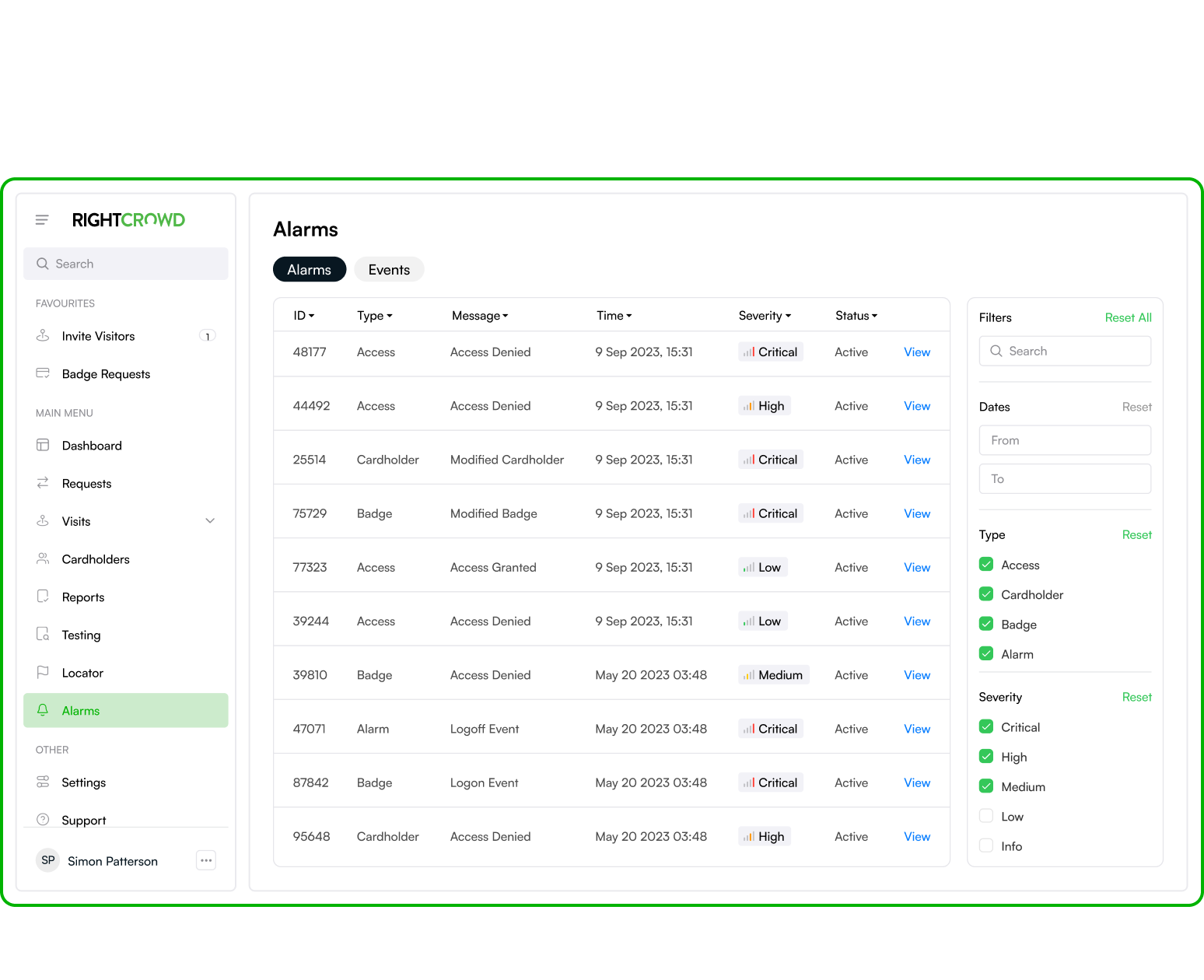

Get In Control of Workplace Contact Tracing

RightCrowd Contact Tracing is the leading all-in-one workplace contact tracing, COVID-19 exposure reporting and social distancing monitoring system. Using proven Bluetooth® Low Energy technology (BLE), each digital badgeholder continuously monitors close contact events across the workplace and enables rapid contact tracing in the event a team member becomes infected with COVID-19.

The system’s privacy and distance settings can be configured to match legal and policy requirements and provide complete anonymity while effectively managing operational risks. It can be quickly deployed and easily moved to other locations as your business grows.

RightCrowd Contact Tracing delivers simple accurate, close contact and COVID-19 exposure reporting. Users can quickly access close contact reporting across location, date/time, duration and 1st, 2nd or 3rd-degree exposure. Mandatory COVID-19 exposure notification can be quickly delivered to exposed workers.

To find out more contact RightCrowd.